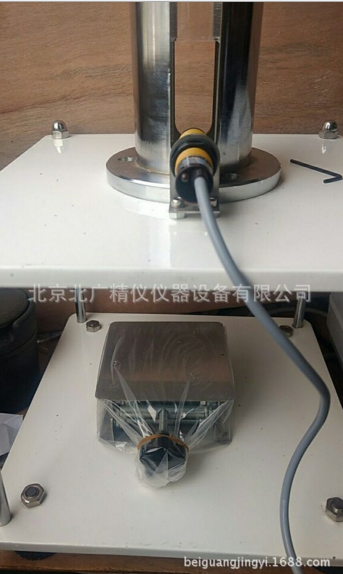

北京海绵落球回弹试验机厂家 主要配置:

1、试验主机一台(含微型打印功能)

2、智能液晶控制操作系统一台

3、钢球释放机构1套

4、钢球捕捉机构(精密光电传感器)一套

5、高度调节机构一组

6、钢球2个

北京海绵落球回弹试验机厂家 适用范围及功能:

适用于测定软质聚氨酯泡沫塑料的落球式回弹性能.海绵泡沫塑料落球回弹测试仪通过标准规定直径和质量的钢球在规定高度上自由落在海绵泡沫塑料试样上,自动计算钢球回弹的zui大高度与钢球落下高度比值的百分率(既回弹率),以回弹率表示泡沫塑料的回弹性能。海绵泡沫塑料落球回弹测试仪采用微处理器进行控制,液晶屏显示中文操作,具有使用操作方便,性能可靠,测量精度高等特点,并可打印试验数据。

Main configuration:

1, a test host (including micro-printing function)

2, a smart LCD control operating system

3. 1 set of steel ball release mechanism

4. A set of steel ball capturing mechanism (precision photoelectric sensor)

5, a set of height adjustment mechanism

6. Two steel balls

实验步骤

将调节后的试样水平置于回弹仪的测试位置上,通过调节使钢球底部从固定位置到泡沫塑料表面的落下高度为460mm。在释放装置上固定钢球,然后使钢球自由落下。对每一个试样做三次回弹,取三次回弹中的最大值。每次回弹钢球应落在试样表面的同一位置上,并且两次回弹的时间间隔应控制在20s之内。如果钢球在回弹过程中碰到或弹出测量装置,所得数据无效,需重新补做。

下列术语和定义适用于本标准。

2.1开孔软质泡沫材料:封闭的泡孔体积小于25%的软质泡沫材料。

2.2闭孔软质泡沫塑料:封闭的泡孔体积大于25%的软质泡沫材料。

原理:具有一定质量和直径的钢球,从固定高度下落到试样表面,测量钢球弹起的高度,计算钢球弹起高度与下落高度比值的百分率。

方法A,测试仪器和主要参数:

海绵落球回弹性能测试仪,包括一根内径30mm~60mm的透明管子,一个直径16mm?0.5mm的钢球,质量为16.8g?1.5g,由磁铁或其他装置释放。下落过程中没有旋转,一直处于中心位置。下落高度为500mm?0.5mm。球顶部距离试样表面应为516mm。因此,零回弹得原点为试样表面上方钢球的直径距离。

如果管子不垂直可能会引起测量误差,钢球在下落或回弹过程中接触管子内壁,测量结果无效。用水平仪或类似装置校准硬基准面以保证水平,并将透明管及架垂直安放。

试验步骤及结果表示:

1.预压状态调节:开孔软质泡沫材料在试验前应先进行预压状态调节。方法是在0.4mm/s~6mm/s速度下,将试样压缩到原始厚度的75%~80%,预压2次来对试样进行预应力状态调节,然后允许试样有一个10min?5min的恢复期。

注:预应力状态调节不适用于3.2中提到的闭孔软质泡沫材料。

试验方法A:

1.按照第8章中规定的条件,状态调节后立即开始试验。

2.将试样放在基准面,调节管子的高度,使零回弹为试样表面上方16mm?0.5mm处。固定管子以确定管子和试样间有轻接触,不引起任何可视的压力。

3.将钢球放在释放装置上,然后释放钢球,记录回弹最大高度整数值。球下落过程中或回弹过程中,如果碰到管子内壁,试验结果无效。发生这种情况,主要是由于管子不垂直或试样表面不均匀。为了减小视觉误差,试验员的视线应与管子上的回弹读数刻度线成水平直线。为了证明视觉水平的准确性,试测是必要的。

4.三个试样分别要在1min内至少得到3个有效的回弹值。

5.结果表示每个试样测得3个结果。如果有一个值超过中值的20%(五分之一),再多试验两次,确定5个值中的中值。从3个样品的中值中,再取中值为样品的回弹率。

自动测量装置显示的结果有效位数取整数。

试验方法B

1.按照第8章中规定的条件,状态调节后立即开始试验。

2.将试样水平置于回弹仪位置上,通过调节使钢球底部从固定位置到试样表面的落下高度为460mm。

3.将钢球放在释放装置上,然后释放钢球,记录回弹最大高度整数值。球下落过程中或回弹过程中,如果碰到管子内壁,试验结果无效。发生这种情况,主要是由于管子不垂直或试样表面不均匀。为了减小视觉误差,试验员的视线应与管子上的回弹读数刻度线成水平直线。为了证明视觉水平的准确性,试测是必要的。

4.三个试样分别要在1min内至少得到3个有效的回弹值。

5.结果表示每个试样测得3个结果,从3个结果中取最大值。再计算3个最大值的平均值作为样品的回弹率。

技术参数:

1、钢球回落高度: 460mm(国标)

500mm(美标)

2、钢球直径: ¢16mm

3、落球回弹率精度: <1%

4、被测试样尺寸: 长*宽*高=100 mm?100 mm?100(50)mm

5、自动计算平均回弹高度

6、自动计算平均回弹率

7、适用于测定软质聚氨酯泡沫塑料的落球式回弹性能。

8、满足08标准A法和B法试验方法。主要是测试塑料泡沫材料及海绵材料的回弹性能。

9、落球回弹测量精度高采用微处理器进行控制,中文显示,并可打印试验数据。

10、落球回弹是通过给定直径和质量的钢球在规定高度上自由落在泡沫塑料试样上,计算钢球回弹的最大高度与钢球落下高度比值的百分率既回弹率,以回弹率表示泡沫塑料的回弹性能。

制造标准:

(GB/T6670-2008 ISO8307 ASTM D3574 ISO8307)软质泡沫聚合材料落球法回弹性能的测定

海绵泡沫塑料落球回弹测试仪通过标准规定直径和质量的钢球在规定高度上自由落在海绵泡沫塑料试样上,自动计算钢球回弹的最大高度与钢球落下高度比值的百分率(既回弹率),以回弹率表示泡沫塑料的回弹性能。

海绵泡沫塑料落球回弹测试仪采用微处理器进行控制,液晶屏显示中文操作,具有使用操作方便,性能可靠,测量精度高等特点,并可打印试验数据。

人工读值设备:

在管子背面有序的按百分比划上刻度线,每5%(25mm)一个大刻度和每1%(5mm)一个小刻度,角度为120?弧线。这个完整的圆周划线是仪器不可缺少的重要部分,它可以排除视差错误。Manual reading equipment:

Mark marks on the back of the pipe in an orderly percentage, with a large scale every 5% (25mm) and a small scale every 1% (5mm), at an Angle of 120?arc. This complete circumference marking is an indispensable part of the instrument, which can eliminate parallax errors.

Automatic reading device:

A device that electronically displays the rebound height of a steel ball has proved to be the same as a manual reading. The height of the rebound can be calculated by the speed of the ball rebound or the time interval between the first and second contact of the ball with the foam surface. The installed electronic device shall display an accuracy of?1% (5mm) of the height. The pipe of such a device does not need to be marked.

Method B, test instrument and main parameters:

The same equipment as method A foam falling ball resilience tester, manual reading value equipment also has automatic reading equipment. The accuracy of the instrument is less than 1.5%, the main parameters of the steel ball diameter are the same as that of method A, and the steel ball mass is 16.3g (0.5g lighter than the 5.1 steel ball). The important different parameters are: the drop height of the steel ball is 460mm?0.5mm. Therefore, the rebound values measured by method A and method B cannot be directly converted.

自动读值设备:

一种能通过电子方式显示出钢球回弹高度的仪器,它已被证实和人工读出的结果是一样的。通过钢球回弹的速度或钢球第一次到第二次接触泡沫表面的时间间隔可以计算出回弹的高度,安装的电子设备应显示出高度的?1%(5mm)精度,这种装置的管子不需要划刻度。

方法B,测试仪器和主要参数:

与方法A相同设备泡沫落球回弹性能测定仪,有人工读值设备也有自动读值设备。数字显示落球回弹仪,仪器精度为相对误差小于1.5%,主要参数钢球直径与方法A相同,钢球质量16.3g(比5.1的钢球轻0.5g)。重要的不同参数是:钢球的下落高度为460mm?0.5mm。使得方法A和方法B测出的回弹值不能直接换算。

Application scope and functions:

It is suitable for determining the falling ball resilience of soft polyurethane foams. Sponge foam falling ball rebound tester through the standard diameter and quality of the steel ball at the specified height of free fall on the sponge foam sample, automatically calculate the maximum height of the steel ball rebound and the percentage of the steel ball falling height (that is, the rebound rate), the rebound rate indicates the resilience of the foam. Sponge foam falling ball rebound tester is controlled by microprocessor, LCD screen displays Chinese operation, has the characteristics of easy operation, reliable performance, high measurement accuracy, and can print test data.

Experimental procedure

The adjusted sample is placed horizontally on the test position of the rebound instrument, and the falling height from the fixed position of the bottom of the steel ball to the foam surface is 460mm by adjustment. Secure the ball on the release device, and then let the ball fall freely. Do three bounces for each sample and take the maximum value of the three bounces. Each rebound ball should fall on the same position on the surface of the sample, and the time interval between the two rebounds should be controlled within 20s. If the steel ball hits or pops out of the measuring device during the rebound process, the data obtained is invalid and needs to be made up again.

The following terms and definitions apply to this standard.

2.1 Open cell soft foam materials: soft foam materials with closed cell volume less than 25%.

2.2 Closed cell soft foam: soft foam material with closed cell volume greater than 25%.

Principle: A steel ball with a certain mass and diameter falls from a fixed height to the surface of the sample, measures the height of the ball bouncing, and calculates the percentage of the ratio between the height of the ball bouncing and the height of the falling.

Method A, test instrument and main parameters:

The sponge falling ball resilience tester comprises a transparent tube with an inner diameter of 30mm ~ 60mm, a steel ball with a diameter of 16mm?0.5mm and a mass of 16.8g?1.5g, which is released by a magnet or other device. It doesn't rotate as it falls, it stays centered. The drop height is 500mm?0.5mm. The top of the ball should be 516mm away from the specimen surface. Therefore, the zero rebound origin is the diameter distance of the steel ball above the specimen surface.

If the pipe is not vertical, the measurement error may be caused, and the steel ball will contact the inner wall of the pipe during the fall or rebound process, and the measurement result will be invalid. Calibrate the hard datum with a level or similar device to ensure level, and place the transparent tube and frame vertically.

Test procedures and results are shown as follows:

1. Pre-pressure state adjustment: The open-cell soft foam material should be pre-pressure state adjustment before the test. The method is to compress the sample to 75% to 80% of the original thickness at a speed of 0.4mm/s ~ 6mm/s, prepress the sample twice to adjust the prestressed state, and then allow the sample to have a recovery period of 10min?5min.

Note: Prestressed state regulation does not apply to closed cell soft foam materials mentioned in 3.2.

Test Method A:

1. Start the test immediately after state adjustment in accordance with the conditions specified in Chapter 8.

2. Place the sample on the datum surface and adjust the height of the pipe so that the zero rebound is 16mm?0.5mm above the surface of the sample. Secure the tube to ensure that there is light contact between the tube and the specimen without causing any visible pressure.

3. Put the steel ball on the release device, then release the steel ball, and record the maximum rebound height integer value. If the ball hits the inner wall of the pipe during the fall or rebound process, the test result is invalid. This happens mainly because the tube is not vertical or the specimen surface is not uniform. In order to reduce visual errors, the tester's line of sight should be horizontal with the rebound reading scale line on the tube. In order to prove the accuracy of the visual level, a test is necessary.

4. The three samples shall obtain at least 3 effective rebound values within 1min respectively.

5. Results indicate that 3 results are measured for each sample. If one value exceeds 20% (one-fifth) of the median value, try it twice more to determine the median of the five values. From the median value of the 3 samples, the median value is the rebound rate of the sample.

The significant digit of the result displayed by the automatic measuring device is integer.

Test method B

1. Start the test immediately after state adjustment in accordance with the conditions specified in Chapter 8.

2. Place the sample horizontally on the position of the rebound meter, and adjust the falling height of the bottom of the steel ball from the fixed position to the surface of the sample to 460mm.

3. Put the steel ball on the release device, then release the steel ball, and record the maximum rebound height integer value. If the ball hits the inner wall of the pipe during the fall or rebound process, the test result is invalid. This happens mainly because the tube is not vertical or the specimen surface is not uniform. In order to reduce visual errors, the tester's line of sight should be horizontal with the rebound reading scale line on the tube. In order to prove the accuracy of the visual level, a test is necessary.

4. The three samples shall obtain at least 3 effective rebound values within 1min respectively.

5. The result indicates that each sample has 3 results, and the maximum value is taken from the 3 results. The average value of the three maximum values is calculated as the rebound rate of the sample.

Technical parameters:

1, steel ball fall height: 460mm (national standard)

500mm (US standard)

2, steel ball diameter:¢16mm

3, drop ball rebound rate accuracy: <1%

4, the test sample size: length * width * height =100 mm?100 mm?100 (50) mm

5, automatically calculate the average rebound height

6, automatically calculate the average rebound rate

7, suitable for the determination of soft polyurethane foam falling ball resilience.

8, meet the 08 standard A method and B method test methods. Mainly to test the resilience of plastic foam materials and sponge materials.

9, high accuracy of falling ball rebound measurement using microprocessor control, Chinese display, and can print test data.

10, falling ball rebound is through the given diameter and quality of the steel ball at the specified height of the free fall on the foam sample, calculate the maximum height of the steel ball rebound and the steel ball falling height ratio of the percentage of the rebound rate, the rebound rate represents the resilience of the foam.

Manufacturing standard:

(GB/T6670-2008 ISO8307 ASTM D3574 ISO8307) Determination of resilience of soft foam polymeric materials by falling ball method

Sponge foam falling ball rebound tester through the standard diameter and quality of the steel ball at the specified height of the free fall on the sponge foam sample, automatically calculate the maximum height of the steel ball rebound and the steel ball falling height ratio of the percentage (i.e., the rebound rate), with the rebound rate to indicate the resilience of foam.

Sponge foam falling ball rebound tester is controlled by microprocessor, LCD screen displays Chinese operation, has the characteristics of easy operation, reliable performance, high measurement accuracy, and can print test data.

业务咨询:932174181 媒体合作:2279387437 24小时服务热线:15136468001 盘古机械网 - 全面、科学的机械行业免费发布信息网站 Copyright 2017 PGJXO.COM 豫ICP备12019803号