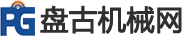

橡胶制品滑动摩擦磨损试验机 试验设备

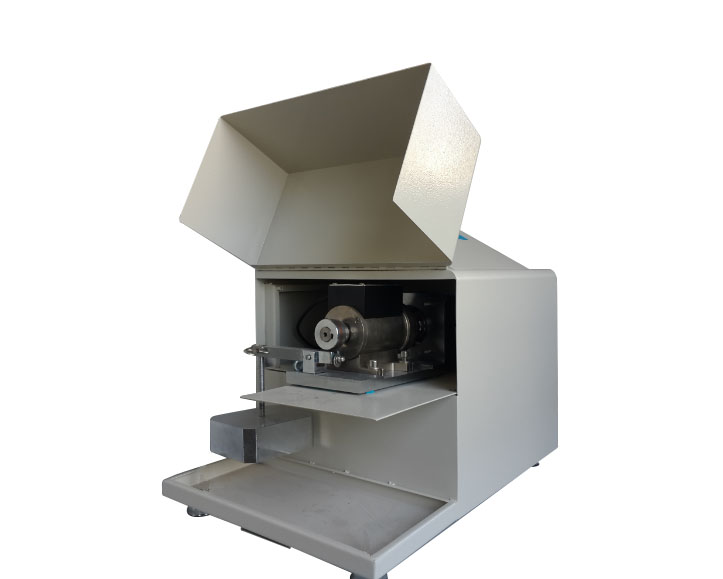

1、传动系统,用来带动圆环以给定的转速旋转,精确到5%以内,并要求圆环安装部位轴的径向跳动小于0.01毫米。

2、加载系统,对试样和圆环,可施加法向力,精确到5%以内。

3、测定和记录摩擦力矩系统,精确到5%以内。

4、记录圆环转数的计数器或记时器,精确到1%以内。

5、试样夹具结构和尺寸见图2,并附配垫圈4 GB 848-76,沉头螺钉M3?0.35长10毫米。要保证试样安置后无轴向窜动。

注:试验设备本标准推荐采用M-200型磨损试验机。

6、本试验中圆环的材质对塑料磨损试验结果影响很大,因此本标准采用的圆环,其外形尺寸见图3。

材料为45号钢,圆环要求整体淬火,热处理HRC 40~45,外圆表面光洁度▽8,倒角处均为0.5?45度,外圆表面与内圆同心度偏差小于0.01.

圆环可以反复使用,每次试验后,需重新磨削。当外径小于36毫米就不能再用。作仲裁试验时必须用直径40毫米的圆环。

注:圆环材质也可按产品标准另定。

橡胶制品滑动摩擦磨损试验机 test equipment

1. The transmission system is used to drive the ring to rotate at a given speed, accurate to within 5%, and requires the radial runout of the shaft at the installation position of the ring to be less than 0.01 millimeters.

2. The loading system can apply a normal force to the specimen and ring, accurate to within 5%.

3. Measure and record the friction torque system with an accuracy of within 5%.

4. A counter or timer that records the number of revolutions of a circle, accurate to within 1%.

5. The structure and dimensions of the sample fixture are shown in Figure 2, and it is equipped with a washer 4 GB 848-76, and a countersunk screw M3?0.35 with a length of 10 millimeters. Ensure that there is no axial displacement of the sample after placement.

Note: This standard recommends the use of M-200 wear testing machine for testing equipment.

6. The material of the circular ring in this experiment has a significant impact on the plastic wear test results. Therefore, the outer dimensions of the circular ring used in this standard are shown in Figure 3.

The material is 45 steel, and the ring requires overall quenching. The heat treatment is HRC 40-45, and the surface smoothness of the outer circle is▽8. The chamfer is 0.5?45 degrees, and the concentricity deviation between the outer circle surface and the inner circle is less than 0.01

The ring can be reused and needs to be re ground after each test. When the outer diameter is less than 36 millimeters, it cannot be used again. When conducting arbitration tests, a circular ring with a diameter of 40 millimeters must be used.

Note: The material of the circular ring can also be determined according to the product standard.

摩擦磨损定义

1、摩擦:两物体接触表面间产生阻碍切向相对移动的现象称为摩擦。

2、滑动摩擦:两接触物体接触点具有不同速度时之摩擦。

3、摩擦力:两物体摩擦时相对移动的阻力。

4、摩擦系数:阻碍两物体相对运动的摩擦力对作用到物体表面的法向力之比。

5、磨损:物体相对运动时相互接触表面的物质不断损失或产生残余变形称为磨损。

Definition of Friction and Wear

1. Friction: The phenomenon of obstructing tangential relative movement between two objects in contact with each other is called friction.

2. Sliding friction: The friction between two objects in contact at different speeds.

3. Friction: The resistance of two objects to relative movement when they rub against each other.

4. Friction coefficient: The ratio of the frictional force that impedes the relative motion of two objects to the normal force acting on the surface of the object.

5. Wear: The continuous loss or residual deformation of materials on the surfaces in contact with each other during relative motion of objects is called wear.

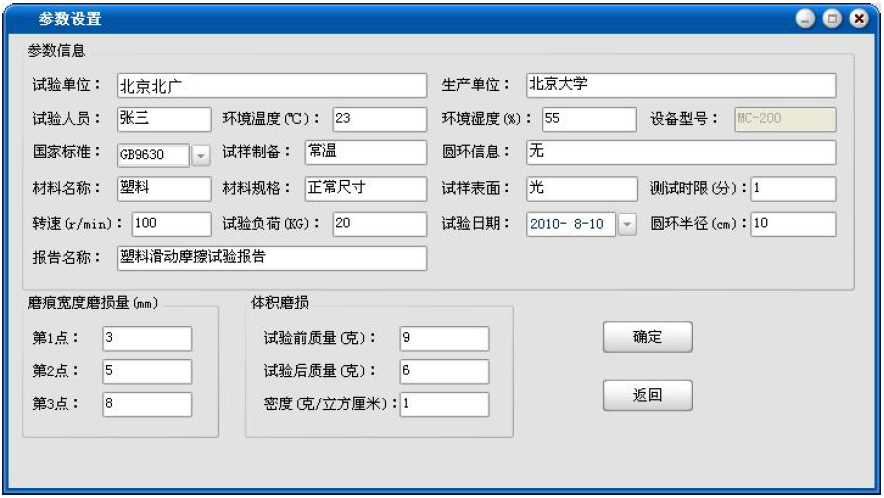

试验报告

试验报告应包括下列内容:

A.塑料名称、规格、牌号、生产厂;

B.试样的制备方法,摩擦表面状况,测定的试样个数;

C.环境温度、温度及状态调节条件;

D.圆环材质、硬度、光洁度和外径尺寸;

E.试验负荷;

F.试验结果:磨痕宽度或体积磨损及摩擦系数的测定结果;

G.试验日期、人员。

Test report

The test report should include the following content:

A. Plastic name, specification, grade, and manufacturer;

B. The preparation method of the sample, the condition of the friction surface, and the number of samples measured;

C. Environmental temperature, temperature, and condition adjustment conditions;

D. Ring material, hardness, smoothness, and outer diameter size;

E. Test load;

F. Test results: Measurement results of wear scar width or volume wear and friction coefficient;

G. Test date and personnel.

功能特点:

1、试样尺寸:30mm?7mm?6mm

2、转动速度:0-500转/分 (可调)

3、负 荷:196N?0.1%(可增至392N)

4、摩擦环尺寸:¢40?10mm,倒角0.5?45?,外圆表面与内圆同心度偏差小于0.01

5、摩擦环材质:45号钢,淬火,热处理HRC40-45,外圆表面光洁度▼8

6、摩擦力矩:0--4N?m

7、砝码重量:4KG砝码一件,1KG砝码4件,可实现重量叠加功能。

Functional characteristics:

1, sample size: 30mm x 7mm x 6mm

2, rotation speed: 0-500 turn / points (adjustable)

3, load: 196N 0.1% (can be increased to 392N)

4, the size of the friction ring is: 40 x 10mm, chamfer 0.5 * 45 degrees, and the concentricity deviation between the outer surface and the inner circle is less than 0.01.

5, friction ring material: 45 steel, quenching, heat treatment HRC40-45, round surface finish 8

6, friction moment: 0--4N. M

7, weight weight: 4KG weight one, 1KG weight 4, can achieve weight superposition function.

主要配置及附件:(计算机控制)

1、试验主机一台

2、高精度扭矩传感器一只

3、计算机数据采集卡一块

4、计算机一台(品牌)

5、彩色激光喷墨打印机一台

6、计算机控制软件一套

7、4Kg砝码两件(备用一套)

8、标准磨擦环四件(备用两件)

9、产品使用说明书一份

10、产品合格证

11、产品装箱单一份

12、整机重量:约87公斤

Main configuration and accessories: (computer control)

1. A test host

2. A high precision torque sensor

3. One piece of computer data acquisition card

4. One computer (brand)

5. A color laser inkjet printer

6. A set of computer control software

7, two 4Kg weights (a spare set)

8, four standard friction ring (two spare)

9. One copy of the product instructions

10. Product qualification certificate

11. Packing a single part of the product

12, the weight of the whole machine: about 87 kilograms

符合标准:

GB/T 3960-1983塑料滑动摩擦磨损试验方法GB/T 9141.8-1999柔性石墨板材滑动摩擦系数测试方法

Conform to the standard:

GB/T 3960-1983 plastic sliding friction and wear test method GB/T 9141.8-1999 flexible graphite sheet friction coefficient test method

适用范围:

适用于塑料制品、橡胶制品、石墨板材或其他复合材料的滑动摩擦,磨损性能测试,也可对试验中试样的磨擦力、磨擦系数和磨损量进行测定。也可对试验中试样的磨擦力、磨擦系数和磨损量进行测定。

Scope of application:

It is suitable for sliding friction, wear testing of plastic products, rubber products, graphite plate or other composite materials. It can also be used to measure the friction force, friction coefficient and wear amount of the test sample. The friction force, friction coefficient and wear volume of the specimens can also be measured.

本机采用高精度扭矩传感器,16位单片机电子处理系统,使得本仪器各项测试指标精度非常高。由于集成程度很高,所以设备本身的稳定性极好,本机具有一次设置,全自动运行,实验结束后自动停机,

并检测磨损程度,同时通过打印机打印试验数据等功能。是各个科研单位,大学,企业实验室的必备检测设备。

本仪器融合了当前最新的智能电路系统进行控制,并结合老式M-200摩擦磨损试验机的功能进行升级改造而成,本仪器具有测控精度高,操作便捷等优势,是科研院所、质检机构、实验室研究首选的试验设备。

M-200型摩擦磨损试验机主要由试验主机及智能控制系统两大部分构成,通过微机控制系统进行操作试验,在试验过程中同时可以显示数值、扭矩、时间曲线,并可以随意设定试验次数,显示当前试验数值。

This machine adopts high-precision torque sensors and a 16 bit microcontroller electronic processing system, which makes the accuracy of various testing indicators of this instrument very high. Due to its high level of integration, the stability of the equipment itself is excellent. This machine has a one-time setting, fully automatic operation, and automatic shutdown after the experiment is completed,

And detect the degree of wear, while printing test data through a printer and other functions. It is an essential testing equipment for various research institutions, universities, and enterprise laboratories.

This instrument integrates the latest intelligent circuit system for control, and is upgraded and transformed by combining the functions of the old M-200 friction and wear testing machine. It has the advantages of high measurement and control accuracy, convenient operation, and is the preferred testing equipment for research institutes, quality inspection institutions, and laboratories.

The M-200 friction and wear testing machine mainly consists of two parts: a testing host and an intelligent control system. The operation test is carried out through a microcomputer control system. During the test process, the numerical value, torque, and time curve can be displayed simultaneously, and the number of tests can be set arbitrarily to display the current test value.

塑料摩擦磨耗的影响因素

1.表面粗糙度的影响:接触表面越粗糙,摩擦系数越大

2.温度的影响:温度对摩擦系数的影响不大

3.负荷的影响:随负荷的增大而缓慢下降

4.速度的影响:中/低速,摩擦系数随速度的增加而增大,高速下,滑动摩擦系数随温度的增加而降低

5.配对材料:与不同材料配对时,其摩擦系数有很大差别

The influencing factors of plastic friction and wear

1. Effect of surface roughness: The rougher the contact surface, the greater the friction coefficient

2. The influence of temperature: Temperature has little effect on the coefficient of friction

3. Impact of load: Slowly decreases with increasing load

4. Impact of speed: At medium/low speeds, the friction coefficient increases with the increase of speed, while at high speeds, the sliding friction coefficient decreases with the increase of temperature

5. Paired materials: When paired with different materials, there is a significant difference in their friction coefficient

温度和速度的影响

1.橡胶的摩擦性能具有明显的粘弹特征

2.摩擦系数是温度和速度的函数,在某一速度和温度下出现极大值

3.磨耗,一般来说,温度升高会使磨耗量增大,随着温度的降低,在玻璃化温度附近,磨耗量达到最小值,然后重新上升。

The influence of temperature and speed

1. The friction performance of rubber has obvious viscoelastic characteristics

2. The coefficient of friction is a function of temperature and velocity, with a maximum value occurring at a certain velocity and temperature

3. Wear, generally speaking, an increase in temperature will increase the amount of wear. As the temperature decreases, the wear reaches its minimum value near the glass transition temperature and then rises again.

环境的影响

周围的气体,液体,湿度对磨耗性能的影响是很大的

1.氧气的存在对疲劳磨耗影响最大,但对粗糙表面上的磨耗影响不大

2.液体介质使橡胶溶胀,从而降低耐磨性

Environmental impact

The influence of surrounding gases, liquids, and humidity on wear performance is significant

The presence of oxygen has the greatest impact on fatigue wear, but has little effect on wear on rough surfaces

2. Liquid media causes rubber to swell, thereby reducing wear resistance

北广产品销往北京、上海、广东、河南、浙江、河北、江苏、湖南、内蒙、山东、四川、广州、江西、西北、云南、深圳、吉林、南京、嘉兴、佛山、苏州、杭州、西安、潥阳、长春、江苏、平顶山、安徽、金水、金华、海南、廊坊、天津、成都、扬州、东莞、济南、南通、株洲、保定、贵州、宜兴、嘉兴、黑龙江、漳州、成都、重庆、咸阳、济南、绍兴、杭州、拉萨、山西、惠州、沧州、江西、沈阳、武汉、沈阳、昆明、鹤山、许昌、青海、宁波、醴陵、淄博、瑞安、阜新、合肥、长沙、常州、瑞安、青岛、无锡、济宁、醴陵、厦门、河源、乐清、烟台、福州、龙口、徐州、唐山等地销售。

业务咨询:932174181 媒体合作:2279387437 24小时服务热线:15136468001 盘古机械网 - 全面、科学的机械行业免费发布信息网站 Copyright 2017 PGJXO.COM 豫ICP备12019803号